New Products

-

Custom Turn-Mill Combination brass parts

-

Custom Turn-Mill Combination parts

-

Precision CNC Turning Parts Stainless Steel shaft accessories

-

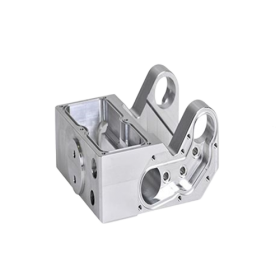

Custom CNC Milling Automated Machinery and Equipment Parts

-

OEM/ODM Custom High Precision Metal CNC Machining/Milling/Turning Service CNC Turning Part

-

Precision CNC Milling Robotic Arm parts

How to Cut Acrylic or Plexiglass Sheets

Acrylic sheets, or plexiglass, composed of poly(methyl methacrylate) (PMMA), are highly workable thermoplastics. Renowned for their clarity, impact resistance, and lightweight properties, acrylic sheets serve as an excellent alternative to glass in numerous applications.

Whether you're manufacturing sleek electronics housings, protective covers, or intricate display fixtures, the ability to cut acrylic sheets precisely without cracking is key. This comprehensive guide delves into common cutting methods, essential tools, and expert tips.

Common Methods for Cutting Acrylic Sheets

1. Laser Cutting

· How It Works: Laser cutting is a highly precise method that uses a focused laser beam to melt and vaporize acrylic, resulting in clean, smooth edges and intricate designs. It's ideal for producing detailed patterns, sharp corners, and high-quality finishes.

· Ideal Applications:

· Electronics Industry: Cutting custom enclosures for smartphones, tablets, and other devices with exacting dimensions.

· Signage and Displays: Creating detailed logos, lettering, and decorative elements for retail displays and trade show booths.

· Jewelry Making: Crafting intricate acrylic jewelry pieces with fine details and smooth edges.

· Advantages:

· High precision and repeatability.

· Minimal post-processing required.

· Capable of cutting complex shapes and designs.

· Limitations:

· Limited to thinner acrylic sheets (usually up to 1/4 inch or 6 mm) due to laser power constraints.

· Higher cost compared to other methods, especially for large-scale production.

2. CNC Routing

· How It Works: CNC routers use computer-controlled cutting tools to carve acrylic sheets, offering versatility in handling various thicknesses, from thin sheets to thick blocks. This method enables the creation of complex shapes, profiles, and custom designs with high precision.

· Ideal Applications:

· Automotive Industry: Fabricating interior trim pieces, instrument panels, and protective covers.

· Furniture Manufacturing: Cutting acrylic tabletops, shelves, and decorative accents.

· Prototyping: Rapidly producing prototypes with accurate dimensions and intricate features.

· Advantages:

· Can handle a wide range of acrylic thicknesses.

· Offers flexibility in design and customization.

· Produces clean, smooth edges with minimal burring.

· Limitations:

· Requires specialized equipment and programming skills.

· Longer setup times compared to simpler methods.

3. Water Jet Cutting

· How It Works: Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through acrylic sheets. This method is highly versatile and can handle various thicknesses without generating heat, preventing material distortion.

· Ideal Applications:

· Marine Industry: Cutting acrylic windows, hatches, and protective shields for boats and yachts.

· Industrial Equipment: Fabricating acrylic covers and guards for machinery and equipment.

· Art and Sculpture: Creating large-scale acrylic art installations with complex shapes and smooth edges.

· Advantages:

· No heat-affected zones, ensuring dimensional accuracy.

· Can cut through thick acrylic sheets with ease.

· Suitable for intricate and complex designs.

· Limitations:

· Higher initial investment in equipment.

· May produce a rougher edge compared to laser cutting or CNC routing, requiring additional finishing.

4. Scoring and Breaking

· How It Works: This method involves using a sharp tool, such as a utility knife or scoring tool, to create a shallow groove (score) on the acrylic surface. The sheet is then snapped or broken along the scored line, resulting in a clean cut.

· Ideal Applications:

· Home DIY Projects: Cutting acrylic sheets for picture frames, tablet stands, and small decorative items.

· Crafting: Creating simple acrylic shapes for scrapbooking, card making, and other crafts.

· Small-scale Repairs: Making quick, straight cuts for replacing damaged acrylic parts.

· Advantages:

· Cost-effective and requires minimal tools.

· Easy to learn and perform, even for beginners.

· Suitable for thin acrylic sheets (up to 1/8 inch or 3 mm).

· Limitations:

· Limited to straight cuts and simple shapes.

· May produce a slightly rough edge that requires sanding or polishing.

Tips for Cutting Thin Acrylic Sheets Without Cracking

· Minimize Heat Generation: Thin acrylic sheets are prone to heat buildup and melting during cutting, especially with power tools. Use lower cutting speeds, sharp blades, and apply cooling methods, such as a mist of water or compressed air, to prevent melting and warping.

· Choose the Right Tool: For thin acrylic sheets, scoring and breaking or using a dedicated acrylic cutting tool, such as a rotary cutter or a fine-toothed saw blade, can help produce cleaner, straighter edges. Avoid using coarse blades or tools that may cause chipping or cracking.

· Secure the Sheet: Properly clamp and support the acrylic sheet to prevent vibration, shifting, or flexing during cutting. Use a sacrificial backer board or a stable work surface to provide additional support and protect the sheet from damage.

· Wear Protective Gear: Always wear appropriate personal protective equipment, such as safety glasses, gloves, and a dust mask, to protect yourself from cuts, injuries, and acrylic dust or fumes. Ensure proper ventilation in your workspace to minimize exposure to harmful particles.

Industry Applications of Acrylic Sheet Cutting

Electronics Industry

Acrylic sheets are widely used in the electronics industry for manufacturing housings, covers, and displays. Laser cutting and CNC routing enable the production of precise, custom-fit components with smooth edges and high clarity, enhancing the aesthetics and functionality of electronic devices.

Signage and Displays

In the signage and display industry, acrylic sheets are popular for creating eye-catching signs, logos, and displays. Laser cutting and water jet cutting allow for the creation of intricate designs and patterns, while CNC routing provides the versatility to produce large-scale, three-dimensional displays.

Automotive Industry

Acrylic sheets are used in the automotive industry for fabricating interior trim pieces, instrument panels, and protective covers. CNC routing and water jet cutting offer the precision and durability required for automotive applications, ensuring a perfect fit and long-lasting performance.

Furniture Manufacturing

Acrylic sheets add a touch of modern elegance to furniture designs. CNC routing and laser cutting are commonly used to cut acrylic tabletops, shelves, and decorative accents, creating unique and stylish furniture pieces.

Art and Sculpture

Acrylic sheets are a popular medium for artists and sculptors due to their transparency, versatility, and ease of manipulation. Water jet cutting and laser cutting enable artists to create intricate, detailed sculptures and installations with smooth edges and precise shapes.

Evan Xiao

Evan Xiao