New Products

-

Custom Turn-Mill Combination brass parts

-

Custom Turn-Mill Combination parts

-

Precision CNC Turning Parts Stainless Steel shaft accessories

-

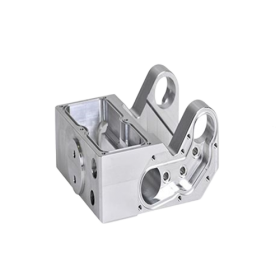

Custom CNC Milling Automated Machinery and Equipment Parts

-

OEM/ODM Custom High Precision Metal CNC Machining/Milling/Turning Service CNC Turning Part

-

Precision CNC Milling Robotic Arm parts

7 Benefits of CNC Machining for Manufacturers

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

CNC machines have become popular due to some key benefits as describe below:

1.With High Accuracy

Produce parts with extremely high levels of precision, consistently meet quality requirements, and eliminate the risks of human error. One of the major CNC machining benefits is accuracy. Because CNC machines receive precise instructions from a computer — and the movements are similarly carried out under computer control — their results will be identical each time and will match the computer model closely. This is a huge advantage when it comes to creating parts with tight tolerances. This capability almost entirely eliminates human error from the equation.

2.With High Production

Produce parts 24/7 provided they are regularly supplied with raw material and fresh cutting tools. Robotic arms can be used to load raw material and unload finished parts with zero human intervention.

3. With High Efficiency

Another industry-cornering CNC machining benefit is the inherent speed and efficiency of production. CNC machines are capable of producing products much more quickly and efficiently than traditional methods. When more conventional milling methods are used, an operator is often required to manually operate the machine and change tooling depending on the cutting operation needed. This can be exceedingly time-consuming and inefficient.

4. With Faster Assembly

Products whose components are created under computer numerical control are simpler to assemble. Because CNC machining is so precise and consistent, companion parts will fit together exactly as they do on the computer. And since the process is quicker than manual machining, you’ll spend less time waiting for parts to be completed. Unless there is a problem in the computer model, all parts should fit together perfectly. This capability can save a lot of time and money in the assembly process, as there is no need for extensive fitting and adjustment.

5. With Reduce Production Costs

CNC machining is an economical, efficient, and precise process of manufacturing parts and products. CNC machining also uses fewer raw materials in comparison to conventional machining. Focusing your shop around CNC technology will drastically reduce errors, production expenditures, and product costs.

6. With Fewer Human Safety Risks

CNC machining removes significant safety risks from the shop floor. By automating the machining process, you can eliminate many of the hazards associated with manual machining. In addition, CNC machines are typically enclosed, which further reduces the risk of injury.

7.With Lower costs

The initial price of a CNC machine may be costly but lower operational costs more than compensate for this. The high output rate, minimal mistakes, and low production costs of CNC machining make it cost-effective. Less training is required, which is a further cost saving.

Operators can also learn how to use CNC machines virtually, eliminating the cost and need for training workpieces. All these factors make CNC machining very attractive.

Conclude:

Such benefits, together with the ability to maintain a high degree of accuracy and minimal waste of material resources, make CNC machining and milling one of the best ways to ensure production is efficient, fast, and scalable with a lower cost liability.

Evan Xiao

Evan Xiao