New Products

-

Custom Turn-Mill Combination brass parts

-

Custom Turn-Mill Combination parts

-

Precision CNC Turning Parts Stainless Steel shaft accessories

-

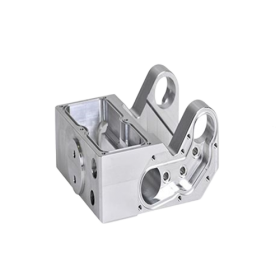

Custom CNC Milling Automated Machinery and Equipment Parts

-

OEM/ODM Custom High Precision Metal CNC Machining/Milling/Turning Service CNC Turning Part

-

Precision CNC Milling Robotic Arm parts

Steps of CNC Machining Service

In modern manufacturing, the precision of part production relies on a systematic workflow that blends design intelligence, material science, and advanced machining technology. This article dissects the core processing steps of CNC Machining services—from digital design to quality validation—highlighting how each stage contributes to the creation of high-precision components.

What is CNC Machining?

CNC machining involves the use of computerized controls to operate and manipulate machine tools, resulting in precise cuts, shapes, and finishes on materials like metal, plastic, wood, and composites. This process is integral to manufacturing because it allows for high accuracy, repeatability, and complex geometries that manual machining cannot achieve.

Step-by-Step CNC Machining Process

1. Design Programming

The Core of Machining Intelligence

Design programming serves as the foundational step, translating conceptual requirements into actionable manufacturing instructions:

· 3D Model Development: Technicians use professional CAD software (e.g., SolidWorks, AutoCAD) to create parametric 3D models, defining geometric features, tolerances (often ±0.01–0.05mm), and surface finishes (e.g., Ra 1.6μm).

· CNC Program Generation: CAM software (e.g., Mastercam, Fusion 360) converts 3D models into G-code programs, optimizing tool paths for minimal material waste and maximum efficiency.

2. Raw Material Preparation

Material Selection & Workpiece Setup

The success of machining hinges on proper material preparation:

· Material Selection: Based on design requirements, materials like 6061 aluminum (for lightweight parts), 304 stainless steel (for corrosion resistance), or PEEK (for high-temperature applications) are chosen.

· Workpiece Clamping: Raw materials are secured on the machine table using vises, magnetic chucks, or custom fixtures to prevent vibration and ensure positional accuracy (≤0.02mm deviation).

3. Tool Selection & Installation

Matching Tools to Machining Demands

Tooling determines the accuracy and efficiency of the machining process:

· Tool Type Selection:

· End mills for milling operations

· Drill bits for hole-making (diameter tolerance ±0.01mm)

· Carbide inserts for turning operations on hard metals

· Tool Installation: Tools are mounted on the tool magazine or spindle with high-precision balancing (≤0.005mm runout), often verified using tool presetter systems.

4. Machining Execution

The Heart of the Manufacturing Process

Once setup is complete, the CNC machine executes the machining program:

1. Machine Startup & Program Loading: The CNC controller initializes, and the G-code program is uploaded, with parameters like spindle speed (up to 40,000 RPM for aluminum) and feed rate (100–2,000 mm/min) activated.

2. Multi-axis Machining Operations:

· Turning: Rotating the workpiece while the tool shapes cylindrical features.

· Milling: Moving the tool across the workpiece to create slots, pockets, or complex profiles.

· Drilling/Tapping: Creating holes and internal threads with precision.

3. Cooling & Lubrication: Water-based coolants or high-pressure mist systems are used to reduce heat buildup, especially for materials like stainless steel that have low thermal conductivity.

5. Quality Inspection

Verifying Precision and Performance

Post-machining inspection is non-negotiable for quality assurance:

· Dimensional Checks:

· Calipers and micrometers for basic measurements (accuracy ±0.01mm)

· Coordinate Measuring Machines (CMMs) for complex geometries (precision ±0.005mm)

· Surface Finish Testing: Portable profilometers (e.g., Mitutoyo SJ-210) measure Ra/Rz values to ensure compliance with design standards.

· Functional Testing: For critical parts (e.g., aerospace fasteners), tensile or fatigue testing is conducted to verify mechanical properties.

Optimizing the Part Manufacturing Process

1. Design for Manufacturability (DFM): Early collaboration between design and manufacturing teams to optimize part geometry for machining efficiency.

2. Predictive Tool Maintenance: Using IoT sensors to monitor tool wear and schedule replacements proactively, reducing unplanned downtime.

3. Digital Twin Technology: Simulating machining processes in virtual environments to identify and mitigate potential issues before physical production.

Partner with Bomei in CNC Machining Services

At Bomei, we pride ourselves on offering comprehensive CNC machining services. Our advanced equipment and skilled machinists enable us to handle a wide range of projects with precision and efficiency.

Contact us today to transform your part designs into high-precision components—from concept to completion.

Evan Xiao

Evan Xiao