New Products

-

Custom Turn-Mill Combination brass parts

-

Custom Turn-Mill Combination parts

-

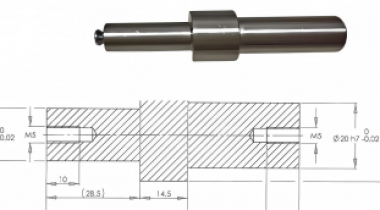

Precision CNC Turning Parts Stainless Steel shaft accessories

-

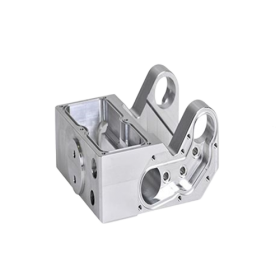

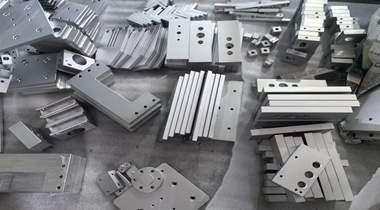

Custom CNC Milling Automated Machinery and Equipment Parts

-

OEM/ODM Custom High Precision Metal CNC Machining/Milling/Turning Service CNC Turning Part

-

Precision CNC Milling Robotic Arm parts

Back to Work From 2026 Lunar New Year

The joyful Spring Festival holiday has drawn to a close, and on this auspicious 8th day of the Lunar New Year, we officially restart work—ready to embrace new opportunities and gallop toward new heights!

2026 is the Year of the (Fire) Horse, a symbol of courage, endurance, drive, and forward...

24/02/2026

More>

Chinese Spring Festival Notice

We'll be closed from Feb 9th to Feb 24th for the Chinese Spring Festival.

09/02/2026

More>

Self-Climbing Aluminum Formwork for High-Rise Building Elevator Shafts: Efficiency & Precision

The core advantage of our self-climbing system lies in its integrated hydraulic lifting mechanism, which enables automatic climbing without the need for cranes or external hoisting equipment.

09/02/2026

More>

How to Control Tolerance in Shaft Parts Machining?

As a professional precision machining manufacturer, Bomei Precision Machining has accumulated rich experience in shaft parts machining over the years. We have successfully solved tolerance control challenges for hundreds of customers in the automation industry, achieving consistent tolerance accurac...

02/02/2026

More>

Automation Machinery Parts Machining Solution: Precision & Efficiency Balance

At Bomei Precision Machining, we don’t just manufacture automation machinery parts—we become an extension of your engineering and production team.

23/01/2026

More>

Discs Round Parts |Bomei Precision Machining

Disc parts are common core components in a variety of machines and equipment, such as various end caps, catch plates, flanges, and flywheels.

14/01/2026

More>

Mill Turning Machining Service | Bomei Precision Machining

Mill-turn machining is widely used in aerospace, medical, automotive, energy, and electronics industries due to its ability to produce complex parts efficiently.

15/01/2026

More>

CNC Small Batch Production: Ideal for Automation Machinery Manufacturing | Bomei Precision Machining

Automation machinery product development is rarely a one-and-done process. Many automation sectors—from industrial robot manufacturers refining end effector designs to packaging automation companies optimizing conveyor components—require multiple iterations before a design is finalized.

08/01/2026

More>

Precision Machining for Measuring & Testing Instrument Industry | Bomei Precision Machining

The future of precision measurement and testing depends on innovation, and innovation depends on machining excellence.

06/01/2026

More>

Happy New Year 2026!

Happy New Year 2026!

31/12/2025

More>

How Material Hardness Affects and Limits CNC Machining?

Material hardness plays a crucial role in CNC machining operations, influencing tool selection, cutting parameters, and overall machining efficiency.

27/11/2025

More>

CNC Swiss Turning

Swiss machining stands out as a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and versatility.

26/11/2025

More>

Low to Mid-Volume CNC Manufacturing

Engineers and procurement teams seek solutions that allow for agility, risk reduction, and real-world testing—without committing to costly tooling or large inventories. This is where low volume CNC machining offers a strategic advantage.

26/11/2025

More>

A Comprehensive Guide CNC drilling

CNC drilling is a critical process in modern manufacturing, offering high precision, consistency, and adaptability across a wide range of applications.

20/11/2025

More>

A Comprehensive Guide to Tolerance in CNC Machining

Accuracy and precision are critical to all machining processes.

Ultimately, these two key performance indicators boil down to one fundamental concept — tolerance.

19/11/2025

More>

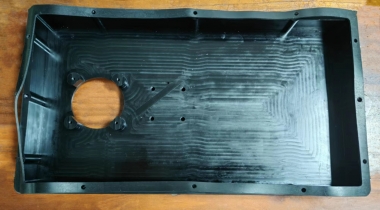

Common Problems and Solutions in POM Plastic CNC Processing

CNC machining of POM offers a multitude of benefits, making it an excellent choice for producing high-quality custom-built parts across various sectors.

18/11/2025

More>

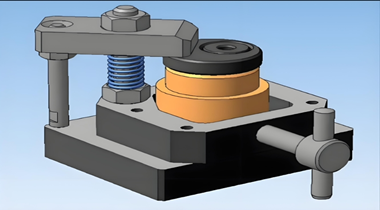

Aluminum 6060T6 Base Plates for Ball Bearing

A ball bearing base plate is a mounting component that secures ball bearings in place, maintaining their position relative to other mechanical parts (e.g., shafts, housings) to enable low-friction rotation.

18/11/2025

More>

CNC Machining for High-Mix Low-Volume Production

The ability of CNC machining to produce high-quality, low-volume parts has become a critical competitive advantage in meeting the growing demand for customization across various industries.

12/07/2025

More>

Guide to CNC Fixtures

Learn about different types of CNC fixtures, it would help to understand that there are situations when certain parts are difficult and near impossible to hold and secure using standard workholding fixtures.

11/07/2025

More>

Guide to High-Mix Low-Volume (HMLV) Manufacturing

High-Mix, Low-Volume(HMLV) manufacturing emphasizes the production of small batches of varied products.

30/06/2025

More>

Evan Xiao

Evan Xiao